Services

Horizontal Turning Centers

Our state-of-the-art turning centers allows us to produce the most advanced products in the marketplace to date. These amazing machines have advanced tooling, capability and output. Haas DS-30Y horizontal turning centers offer the best performance in the

class, and are perfect solutions for a wide range of applications from

small component machining to large-size processing. These turning centers feature separate-spindle multi-axis machining to

perform everything from milling and turning to completion of the most

complex shape with single chucking.

Pallet Pool Milling Center

VMI's Haas Milling Center is designed for high-volume production and unattended operation, the all-new EC-400 is faster, more compact, more rigid, and more capable than ever before. It features a larger work envelope, faster rapids, a full 4th-axis rotary system for synchronous motion, and much better chip management. For extended production and true “lights out” capability, a 6-station pallet pool and high-capacity tool changer are available. NOTE: The Pallet Pool requires the optional 50+1 or 100+1 side-mount tool changer.

CNC Mills

VMI's Haas CNC Mills are capable of complex 5th axis machining from prototype work to regular production machining. We utilize innovative fixturing which is designed to optimize production machining.

For example, our UMC 750 SS is a 5-axis 40-taper vertical machining center with an

integrated dual-axis trunnion table with travels of 30″ x 20″ x 20

suited for most machine shops

The UMC-750’s dual-axis trunnion table can position parts to nearly

any angle for 5-sided (3+2) machining, or provide full simultaneous

5-axis motion for contouring and complex cnc machining.

5 axis machining is unique in its ability to effectively process part

sizes and shapes with essentially infinite possibilities. Like 3 axis

machines, the cutting tool of a 5 axis machining center moves across the

X, Y, and Z linear axes, but also rotates on the A and B axes –

allowing the cutting tool to approach components from any direction. An

experienced machinist can achieve incredibly complicated geometries with

high precision when using all 5 axes in conjunction.

CNC Lathes

VMI's Haas CNC Lathes are used for all simple to complex parts. We will accommodate prototype work no matter how difficult the job. These machines also use automatic bar feeders to maximize production time.

Single Spindle Department

VMI's single spindle automatic machines are used for short production runs and secondary operations. The capacity for these machines are from 1/8" to 3 inches in diameter.

FANUC ROBOCUT EDM

The FANUC ROBOCUT α-C600iC is a high-precision wire Electrical Discharge Machining (EDM) machine designed for reliability, user-friendliness, and advanced performance, built upon 40 years of FANUC EDM technology. Key features include its latest FANUC control with an iHMI, an improved Auto Wire Feed (AWF) system for fast and reliable rethreading, and software for remote monitoring and production management, minimizing downtime. The machine also boasts new design elements, such as a compact chassis with an integrated chiller, a durable table, and a more user-friendly taper adjustment function, making it suitable for complex parts, molds, and automated production.

Secondary Finishing Department

VMI's secondary and finishing department will provide the following: custom assembly of product, buffing and grinding of parts, custom hand operations, drilling, threading, tapping, milling, tumbling, deburring and broaching.

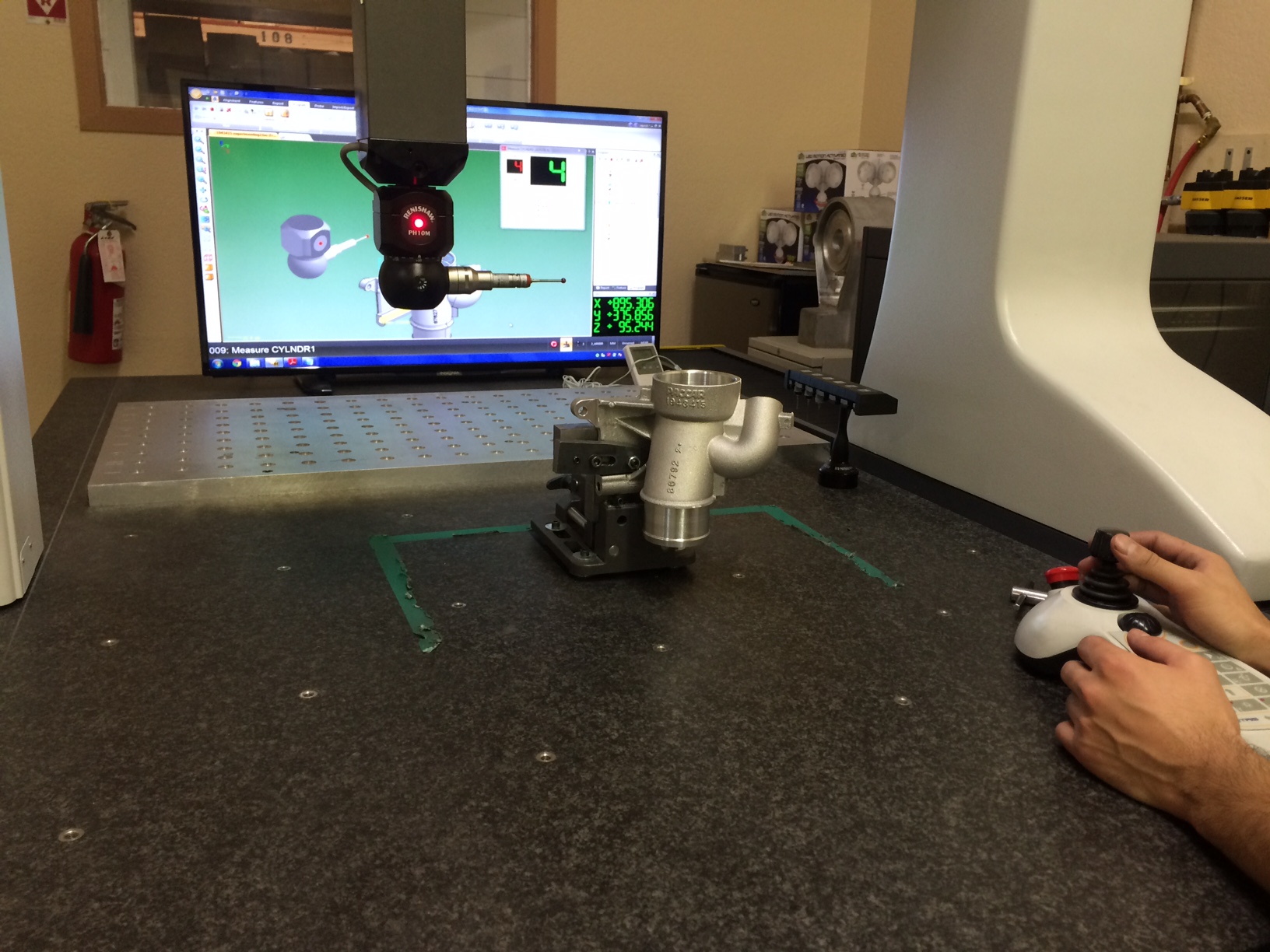

Quality Control

& Inspection

At VMI quality is our highest priority. Our highly trained, fully equipped QC Department is involved with your product from pre-production planning, first article in-process and final inspection. We employ a wide range of tools to monitor quality and capability. SPC, zero defects sampling, military sampling and computerized data collection are used for process analysis with direct feedback to machine operators. The latest in optical measurement and coordinate measuring machines are used to verify dimension specifications. All measuring devices are controlled, calibrated and traceable to the National Bureau of Standards. VMI considers all aspects of our service to our customers as a part of our quality program. Through this program, VMI is AS9100D & ISO 9001:2015 certified and maintains all ISO Quality Standards.

Raw Materials

VMI has gained a great deal of knowledge machining different materials. We have the following experience with these materials: stainless steels, steels-inconel,tool steel, kovar, nickel alloys, titanium, brass, copper, aluminum, plastic, forgings, castings and tubing. We are very familiar with these materials and the different shapes and grades to provide customers with valuable machining advise.

Shipping & Receiving

VMI takes pride in providing quality work and prompt delivery of product. We have taken this high level of service and demanded the same from our outside vendors and freight carriers. In general, our shipping department is capable of any task that is asked of them. We package finished product with custom boxes, bags, pallets, bar codes and any other predetermined procedures. We also utilize ultra-sonic cleaning equipment to ensure your product is to spec. VMI has experience with USMCA and various import-export documentation. We are determined to do what it takes to get our customers product to them in a timely, safe and efficient manner.

If you need to check on the status of your parts contact us for the tracking number

and use the links below to trace your parts:

If there are any specific questions that need answering, please search through our Contact Us page to find the individual that can best help you.

|