Press Releases

March 20th, 2025

WASHINGTON, DC –

The American Edge Project, a coalition of two dozen domestic organizations, today launched a new ad campaign featuring a veteran-owned manufacturing business. The two ad spots highlight the critical role American technology and artificial intelligence (AI) play in strengthening domestic manufacturing, fostering economic growth, and maintaining America’s competitive edge against China.

The first ad, “VMI,” emphasizes the importance of American leadership in open-source AI development and the need to stay ahead of global competitors in technological innovation. The second spot, titled “Vineburg,” features the personal testimony of a U.S. Army veteran who founded Vineburg Machining, a successful manufacturing company now employing 40 people, and explains how American technology and AI are driving business growth.

“American innovation in artificial intelligence and technology is fueling small business success and economic growth,” said Doug Kelly, CEO of the American Edge Project. “We must ensure that America continues leading in these technologies by supporting policies that foster innovation, investment, and long-term economic strength.”

BACKGROUND:

The American Edge Project is a coalition of domestic organizations representing a cross-section of U.S. innovators who are dedicated to telling the story about technology’s positive influence on America’s economy and the vital role innovation plays in our society. Former New Mexico Governor Susana Martinez, former U.S. Representative Chris Carney, and former Federal Election Commission Chairman Bradley A. Smith are directors of the American Edge Project. AEP’s National Security Advisory Board is comprised of Former White House Counterterrorism and Homeland Security Advisor Frances Townsend; retired four-star General Joseph F. Dunford Jr., United States Marine Corps (USMC), who served as former Chairman of the Joint Chiefs of Staff; and former Acting Director of the Central Intelligence Agency (CIA), Michael J. Morell. Former U.S. Senators Saxby Chambliss (R-GA) and Kent Conrad (D-ND) serve as Co-Chairs of the Project’s Economic Advisory Board. Former U.S. Representative Greg Walden (R-OR) and Former U.S. Representative Loretta Sanchez (D-CA) serve as Co-Chairs of the Project’s Open & Accessible Internet Advisory Board.

Visit AmericanEdgeProject.org for more information.

##

MADE IN NEVADA: Vineburg Machining

Vineburg Machining can manufacture almost anything from a tube or block of metal just as Michelangelo produced David from a large marble slab.

Have you ever use Google? The cameras used to capture images of your neighborhood are attached to cars with a mount made by Vineburg Machining.

Critical parts for the M240 machine gun are also produced by Vineburg Machining before they're sent to U.S. Ordnance in McCarran, Nevada for final assembly. The gun is used to defend the United States against ISIS and the Taliban. Its bullets weigh 1/10 of a pound and can pierce through an inch of steel.

Vineburg Machining also makes fasteners to hold wire in place in the walls of most passenger and military jets. These are examples of thousands of parts the northern Nevada business produces.

Each part is produced at the company's warehouse about 13 miles northeast of Carson City at 26 Stokes Drive in Mound House. The products produced there are often extremely high-end parts. Other companies turn to Vineburg Machining when China can't make the parts they need.

Sven Klatt is the general manager. "We never say no. So if customers come in with very complicated stuff it's maybe not possible at first glance. We usually pull it off somehow."

The possibilities at Vineburg Machining are essentially endless because of its advanced machines. Many other manufacturing companies in China or the United States simply don't have them.

"The advantage we have with the five-axis machine is we can move the five axis all at the same time," said Klatt.

The five axis points controlled by a precision computer can produce basically anything, just as Michelangelo produced David from a large marble slab.

"This is a gun slide we make, and it starts out as a routine piece of steel and when we're done with it, it basically becomes this," said Klatt.

The production is staggering. Thirty-three workers produced 4 million parts in 2017 alone.

The company can only do this with the help from robots. One is called the universal robot because it can do so many things. It can make a high security lock for Schlage. It could end up on a cruise ship or in a prison.

This arm can work 24 hours a day and seven days a week. Klatt monitors it from his phone thanks to a camera set up near the robot.

This CMM Coordinate Measuring Machine checks the work after it's done to make sure each part is true to the blueprint. The precision optical measuring of this machine can be mind boggling.

"If you split a human hair about 15 times, that one piece would be about 2-one-thousands of an inch," said Vineburg Machining employee Bill Poleshuk.

"We're talking cutting hair from the top to bottom right?" asked KOLO 8 News Now's Noah Bond.

"Top to bottom, correct," Poleshuk responded.

The story of Vineburg Machining's high-end approach starts in 1961 when the company's President and CEO Gerd Poppinga started his machining apprenticeship in Germany where he grew up. He moved to the United States and started Vineburg Machining in Sonoma, California in 1977.

"We were in the high-volume machining industry and it went pretty well up until the mid-'90s, when a lot of my customers were asking me to lower my prices and said if I wouldn't they'd go overseas," Poppinga said. Many of his customers went overseas.

Then the recession of 2001 shrunk his workforce from 100 employees to only 35. Combine California's higher taxes with this hardship and he felt compelled to move his business to Nevada in 2003. Seventeen families chose to follow him to the Silver State.

By Noah Bond

Posted: Tue 3:14 PM, Mar 06, 2018 |

Making the Move to Five-Axis

After the recession, Vineburg Machining Inc. started taking on challenging medical work, which meant taking up five-axis machining. Machinery from Haas helped cut scrap, reduce processing time and improve quality.

Case Study From: 3/1/2016 Modern Machine Shop, Edited by Emily Probst , Associate Editor

As the business climate began to change around the year 2000, Vineburg Machining Inc. was at a tipping point. Its customers were sending work to China to save money, and owner Gerd Poppinga knew he had to take drastic measures to reduce costs. He packed up his shop, and moved operations and willing employees from California to Lyon County, Nevada, where the tax rates were lower and the cost of living was more affordable. Of course, there was more to the move than a new address. Mr. Poppinga also challenged his employees to change their high-volume mindsets and pursue more challenging manufacturing applications. By adding five-axis capabilities from Haas Automation Inc. (Oxnard, California), the company was able to take on medical work.

Vineburg’s history is one of adaptation. Soon after Mr. Poppinga and four investors bought an Acme-Gridley machine shop that was closing its doors, he began looking for alternatives to cam-driven machines. In the mid-1980s, he purchased several used NC machines and eventually a CNC lathe. By 1997, the other partners had left the company, and Mr. Poppinga grew the business. However, when the recession hit, the shop was asked to lower its prices, and high-volume work started to dwindle. That’s when Mr. Poppinga decided to pursue more challenging work with customers who wouldn’t “beat him up for a nickel per part.” Screw machine work would remain as a steady portion of the shop’s income, but CNC was the future.

That future began to coalesce when Vineburg purchased its first Haas machining center, a VF-3SS, to which it added a TR160 trunnion for five-axis machining capability. General Manager Sven Klatt had been struggling with high scrap rates on a difficult medical part, and the ability to machine multiple sides of the workpiece in a single operation brought immediate benefits. “The new machine eliminated setups and allowed us to run complex parts in a much more efficient manner,” he says.

Happy with the performance of its first machine, and seeing potential to run similar jobs, Vineburg decided to purchase a second trunnion-equipped Haas VF-3SS a few months later. With this acquisition, the company found it could eliminate additional operations on a tool-steel part, one that was previously rough-machined before being heat-treated to 63 Rc. By cutting the part in its hardened state, the company reduced processing time and increased quality.

“Things really started to snowball from there,” Mr. Klatt explains. “Mr. Poppinga and I both came to the same conclusion: If we wanted to get into major-league machining, we had to do it right, and Haas was a big part of that. We’re a 24/7 shop, and the maintenance technician won’t hesitate to come in nights, weekends or do whatever it takes to keep us running.”

Vineburg says it also tries to go the extra mile for its customers. For example, a customer from the UK needed custom muzzle brakes for an AR-style gun machined from 4140 material in two weeks. This was no small feat, as the part’s overall features are very complicated. After receiving the CAD drawing, Mr. Klatt worked the weekend, and the shop was able to deliver the parts as promised. Two years later, Vineburg is still making 2,000 of the parts each month.

Today, the shop has 32 employees and 18,000 square feet of manufacturing space. The single Haas machine has been joined by nine others, with the most recent addition being a UMC-750SS. Three of the machines are UMC-750 machining centers, which Mr. Poppinga and Mr. Klatt first saw at an EMO machine tool exhibition in Hannover, Germany. Right away, the machine proved to be a game changer for the small but growing shop. The affordable five-axis milling machine enabled the shop to evaluate the type of work it was taking on along with its production methods. “It afforded us the ability to offer complex machining to existing and new clients, making us more profitable,” Mr. Poppinga says.

When the UMC-750 arrived, Mr. Klatt ran some parts for the foundry up the street from the shop. It was enough work to book the machine solid. Within one week of receiving the first UMC-750, Vineburg ordered another. Similar experiences drove Vineburg to order additional machines. In fact, one such job was a prosthetic knee component made of cobalt chrome alloy. Prior to the UMC-750’s arrival, Mr. Klatt and his team were making the part in eight operations and suffering 30 percent fallout due to scrap. They retooled the job for the new machine and are now making the knee implant in two operations—turning and milling—with virtually no scrap, he says. Moreover, the move cut 15 minutes off the cycle time.

Another part, this one a component for a military program, is made from 8620 alloy steel that is later induction-heat-treated. Vineburg was having quality problems with distortion from the heat-treating, so it decided to simply finish-machine the parts after hardening. “The Haas had no problem cutting the steel, even at 48 Rc, Mr. Klatt says. This is due to the machine’s rigidity, five-axis table and continuous five-axis movement. “We completely eliminated the quality issues. It seems like every time a machine comes in, it gets filled up before the tech finishes installing it,” he says. “People find out we have this capability, and the phone starts to ring. We’ve been lucky.”

(Click Images to Enlarge)

Vineburg employees had to change their

high-volume mindsets to pursue more challenging

manufacturing applications. In the CNC milling

department, employees now use Haas machines

to accomplish this.

Vineburg uses custom fixtures to

complete complex five-axis milling applications.

The shop uses a Nikon CMM to perform

quality control on a casting machined for

the trucking industry.

UMC-750SS Spotlight – Vineburg Machining Inc.

Vineburg Machining, Inc.

has been manufacturing high-quality machined parts since opening their

doors in Sonoma, California, in 1977. Since then, Vineburg has moved

shop to Carson City, Nevada, and added a number of Haas CNC machines to their arsenal, including a new UMC-750SS vertical machining center. When compared to the production from their UMC-750, Vineburg saw a 16 percent reduction in cycle time with the Super-Speed machine. Take a look at the stats below to learn more about how Vineburg is saving time and money.

Application Highlights:

-

Machine running 24 hour shifts, six days per week

-

Saw improved part finish due to higher spindle speeds

-

Reduction in lost motion (no-cutting) time due to faster rapids

Machine Comparison:

Parts and Material:

Industry:

Customer:

Vineburg Machining, Inc.

Carson City, Nevada

After the recession, Vineburg Machining Inc. started taking on

challenging medical work, which meant taking up five-axis machining.

Machinery from Haas helped cut scrap, reduce processing time and improve

quality.

Case Study

From:

3/1/2016

Modern Machine Shop,

Edited by

Emily

Probst

,

Associate Editor

Heller:

area manufacturing capability is a hidden gem

Adam Trumble

/ Nevada Appeal | Adam Trumble / Nevada Appeal

Sen. Dean Heller

talks with Sven Klatt, the general manager of Vineburg Machining

Inc., and Gerd Poppinga, Sr., founder, of Vineburg on Wednesday.

Sen. Dean Heller

visited Vineburg Machining, Inc., in Mound House on Wednesday and

said the world doesn’t know the hidden gem Northern Nevada’s

industry is.“People don’t

realize the great work that’s going on in this area,” said the

U.S. senator, who told Vineburg’s brain trust he grew up spending

much time in a similar business his father had in Carson City.

“Just so you

guys know, I grew up in a machine shop,” he said. “So it’s

great to be here.”

The occasion for

the visit was a tour of Vineburg with Gerd Poppinga, Sr., the

founder, president and CEO, Sven Klatt, the general manager, and Gerd

Poppinga, Jr., vice president, as well as representatives from

Advantage Capital Partners. Advantage

Capital infused $2.75 million in loan money under a federal-state

program into the expanding machine shop under a New Markets program

nationwide.

Before the tour,

Heller peppered the Vineburg executives about their machining work,

the new equipment made possible by expansion money, the firm’s

history and its customers.

Klatt said Tesla

Motors coming to Nevada, and the new machines are “opening doors”

and the company currently has 134 active customers ranging from other

local manufacturers like Click Bond, Inc., to national and

international firms. He said much of

the business from other area firms was garnered mainly by word of

mouth over the years. He also credited the firm’s craziness at

rarely turning away work.

“We have the

‘yes, we can’ attitude and the new equipment,” Klatt added.

The founder

mentioned his firm came years ago from California as a survival move.

He recalled California days in tough times, when he decided “we

can’t do it here; it’s too expensive.” He said he

brought along nearly 20 key people in his move of the firm to

Northern Nevada.

The Advantage

Capital representatives on hand were Steven Stull and Scott Murphy,

the latter a former congressman from upstate New York who had served

with Heller in Congress before returning to the private sector.

Murphy told

Heller Advantage Capital had selected Vineburg for the loan program

money last year because the executives there knew how to keep

efficient in good times and bad, and are committed to training

skilled workers.

Men and their machines: Carson City area execs head to native Germany

Two top executives from Vineburg

Machining here, both of whom are natives of Germany, return there late

this week building bridges via contacts by working with a Nevada trade

mission.

Gerd G. Poppinga,

president/CEO of the Mound House corporation, and Sven Klatt, the

general manager, head for Berlin to hook up with the trade mission to

Europe led by Gov. Brian Sandoval. The pair, both trained in Germany

before coming to Carson City, will be on hand to promote ties and look

toward planting seeds for eventual worker training and pipelines,

possible exchanges and enhanced Nevada industry training programs.

“It’s going to show really nicely how big companies and small companies

(there) work together to train the entire work force,” said Klatt, who

also teaches manufacturing skills here at Western Nevada College (WNC).

Poppinga agreed.

“I’m sure that the governor is going to be impressed,” the president and CEO said.

Poppinga, Vineburg founder, as a young man worked at a German firm that

later became Electrolux. He did the apprenticeship training program

there and at a trade school. Klatt, working for the same firm a

generation later, did similar combined industry/trade school training.

He subsequently joined Poppinga here and manages a staff of more than 30

working with various machines, including state-of-the-art Five-Axis

units Poppinga calls the pinnacle of the trade.

Klatt chimed in the computer software involved in precision machining

work the firm does has made significant advances in the past decade, so

the combination means ongoing training is crucial.

He said planting seeds for worker exchange is in too preliminary a

stage to talk much about, but he did share Vineburg intends to send a

worker to Germany to undergo perhaps a year of advanced training.

Poppinga said the combined industry/trade school work and

apprenticeship program he and Klatt went through took more than three

years. One day each week was in trade school classes, the rest at the

manufacturer for which they worked. Even at the firm, he said, classwork

training was included along with the work. Employees took a turn in

various roles to learn machining, milling and other necessary tasks, the

pair said, and there were continual tests.

“It is really too bad we don’t have that here,” Poppinga said. Klatt,

however, noted efforts by Northern Nevada educators and others to

provide pertinent education or training for people entering

manufacturing are growing.

Poppinga

lamented the fact workers are needed now and that “everyone focuses on

engineers,” though well trained workers with proper skills also are

crucial. “They have to have a skill set,” he said. “We’re not up on

that. We need to do better.” Klatt said the trade mission, programs at

community colleges like WNC and even at the high school in Carson City

show understanding is growing and progress is possible. “This trip shows

everyone cares,” he said.

Both men,

however, stressed word of opportunities in industry needs to reach

students and their parents so more will consider entering the

manufacturing field. Poppinga cited one Vineburg employee who’s in his

20s and makes $50,000 annually, has no student debt and has the skill

set that makes him valuable long term.

The European trade mission includes five nations and involves the

governor, his office of economic development, others in the economic

development field and various representatives of government, business

and industry. Among those in the delegation is Nick Marano, Carson

City’s city manager, who’s focused on luring technology companies to

Nevada’s capital from Poland.

Also on

the itinerary are Ireland, England and Italy along with Germany and

Poland. The pair of executives from Vineburg is spending about a week in

Germany from Friday through July 30. Poppinga and Klatt said they will

join the delegation in Berlin and travel with it to Dresden and Leipzig

with stops that include major manufacturers like BMW, a BMW supplier,

Porsche and a Collaboration Workforce Training Center.

Poppinga said his machining firm likely is the smallest from industry

here joining the trip, saying larger local manufacturers like GE Bently

in Douglas County and Click Bond in Carson City as also sending

representatives.

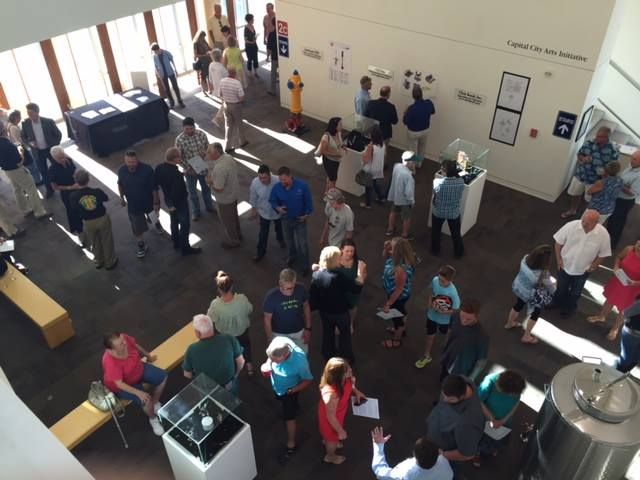

Industrial Art Exibition at the CCAI Courthouse Gallery

Carson City, Nevada — Embracing

the area's design and manufacturing community, the Capital City Arts Initiative

[CCAI] announces its exhibition, Industrial Art, at the CCAI Courthouse Gallery

from June 9 – September 17, 2015. CCAI will host a reception for the show on

Friday, June 12, 5-7pm including a short introduction of the exhibition

participants at 5:30pm. The Courthouse is located at 885 E Musser Street, Carson

City.

The reception and the exhibition are free and the public is cordially

invited. The gallery is open to the public Monday – Friday, 8am –

5pm.

Industrial

Art presents the

design work of five manufacturers in the Carson City area including American

AVK, CGI Inc., Click Bond Inc., Silver State Stainless, and Vineburg Machining

Inc. These companies manufacture products with innovative design that applies to

an array of commercial applications. CCAI presents these products, created for

specific industrial uses, as items to be admired in their own right for their

design, precision, and beauty.

American AVK in

Minden manufactures fire hydrants, objects so common place that we tend to not

notice them, with colorful housings containing many precision valves.

CGI Inc.

creates products for a variety of industrial applications from precision

gearboxes to electro-mechanical items for aerospace systems to semiconductor

applications.

Click Bond Inc., home of the original adhesive bonded fastener,

specializes in ways to fasten items together with structural adhesives for the

international aviation industry. Silver State Stainless manufactures stainless

steel tanks for the beer, wine, and food industries.

Vineburg Machining Inc.

creates precision-machined components for the aviation, automotive, and medical

fields. Each of these firms relies on product design and research to keep them

on the leading edge of their industries.

The show

includes a brew tank constructed by Silver State Stainless specifically for the

exhibition, a fire hydrant, and numerous gears, prosthetic devises, and

intricate elements. Many of these internal and vastly unappreciated components

are critical to keeping our world running and on time.

Artist and

writer Chris Lanier has written the exhibition essay for Industrial Art. He has a background in both traditional

and digital media, and has worked in multimedia performance, digital animation,

web production, and comics. Mr. Lanier is also an essayist and critic whose art

criticism has appeared in a variety of online and print publications. He is an

Associate Professor of Digital Art at Sierra Nevada College, Incline Village,

Nevada. Lanier earned his M.F.A. in

Studio Art at the University of California, Davis in 2007 and his B.A., Art and

Society at the New College of California, San Francisco in 1994. He lives in

Reno with his family.

This exhibition

is supported with a donation from the Northern Nevada Development

Authority.

The Capital

City Arts Initiative is an artist-centered organization committed to the

encouragement and support of artists and the arts and culture of Carson City and

the surrounding region. The Initiative is committed to community building for

the area's diverse adult and youth populations through art projects and

exhibitions, live events, arts education programs, artist residencies, and

online projects.

CCAI is funded

in part by The Andy Warhol Foundation for the Visual Arts, National Endowment for the Arts, John Ben Snow

Memorial Trust, Nevada Arts Council,

City of Carson

City, NV Energy Foundation, U.S. Bank Foundation, Nevada Humanities

and the National Endowment for the Humanities,

Comstock Foundation for History and Culture, and the John and Grace Nauman

Foundation.

For additional

information, please visit CCAI’s website at

www.arts-initiative.org.

Article in Summer/Fall 2014 Viewpoint Magazine

A MOVE WORTH CELEBRATING!

Gerd E. Poppinga, Jr.

Vineburg Machining, Inc.

Est: 1977

Vineburg Machining was founded by Gerd G. Poppinga Sr. Joined by his

son, Gerd, Jr., the Poppinga’s faced competition in the high volume

machining industry from international companies and realized they would

need to adapt to survive. In order to make the necessary changes, the

company focused on cutting costs and producing high quality, complex

products for specific industries. . . .

Carson City Mayor visits Vineburg’ open house, tour

During

a short trip to tour a Mound House machine plant, Carson City Mayor

Robert Crowell said Thursday that manufacturing is an important slice of

life in the city and region.

“In my language, it creates wealth,” he

told Gerd Poppinga, founder and president of Vineburg Machining.

The

firm’s new and expanded plant makes machine parts for medical, transport

and other industries.

The mayor said the industrial park to which

Vineburg moved from a smaller plant seems to have grown since he last

visited, and he plugged regional manufacturing growth. He also said a

larger pool of skilled labor for such technical work is important,

decrying the current situation.

“I just wish there were a bigger

pool,” he said. The mayor supports retaining a strong Western Nevada

College in part because it helps train such workers. Sven Klatt,

Vineburg general manager who was helping with the tours, teaches at WNC

and wants the same growth in the number of skilled workers about which

Crowell spoke.

Poppinga told the mayor there are thousands of such

workers in Germany. Both Poppinga and Klatt, a generation apart, got

their machining educations in the same place before emigrating to the

United States.

The tour was part of back-to-back events involving a

meeting of 26 members from the manufacturers’ forum of the Northern

Nevada Development Authority (NNDA), followed by the open house and

tours. On hand along with the mayor were a host of manufacturers,

skilled-worker-training experts and manufacturing development

representatives or supporters.

Among the latter group were Kris Holt

of Nevada Business Development, Andrew Haskin of NNDA, Roger Kadz of the

Nevada State Development Corp. and Ray Bacon of the Nevada

Manufacturers Association.

There were even representatives of the

Carson City Arts Initiative (CCAI), touting four art pieces associated

with industry themes that Poppinga and they were displaying at the new

Vineburg headquarters.

Sharon Rosse and Glenn Clemmer were among the 75

people or so that Vineburg says attended in their bid to promote

manufacturing.

“Our primary goal is to make Northern Nevada a major

player in the manufacturing industry,” Poppinga said in his invitation.

The open house and tours were to run from 4 to 7 p.m.

John Barrette

jbarrette@nevadaappeal.com

March 14, 2014

China vs. N. Nevada in manufacturing battle

Manufacturers from Carson City and the area

have Chinese rivals in the cross hairs if Nevada taxes or regulations don’t

spoil their aim, according to regional light-industry

leaders.

That was the gist of remarks Wednesday at a

breakfast meeting of Nevada Business Connections, a private-sector economic

development networking organization based in Northern Nevada. Frank Dutra, who

is with Advanced Machining Techniques and Hubzone Manufacturing in California

and Nevada, made those comments during a panel

presentation.

“It’s not as cheap as it was to manufacture in

China,” said the man who moved some of his operations to Minden in recent years.

“I really think that Nevada could be a major competitor with

China.”

Dutra said several original equipment

manufacturers he deals with have bad experiences with Chinese work. Texas is a

primary competitor with Nevada in the United States, Dutra also

said.

Gerd Poppinga and Sven Klatt of Vineburg

Machining, which has a Carson City address and is in a Mound House industrial

park, talked about Vineburg expansion as Klatt took a bead on China. Poppinga,

the founder, and Klatt, the general manager, both came from Germany. They talked

of their German training and state-of-the-art machines while explaining

Vineburg’s survival to the current growth mode.

“I really think that Nevada could be a major competitor with

China.”

Frank Dutra

of Advanced Machining Techniques and Hubzone

Manufacturing

“I feel manufacturing is in a great trend right

now,” said Klatt, adding that Chinese industry no longer has an edge. Both

Poppinga and Klatt talked about the importance of teaching young people advanced

machining skills and other business matters related to light industry. Klatt

said that from his perspective, a crucial factor is “major league machining or

none.”

Also on the panel of manufacturers was Stephen

VanDerver of Vital Systems in Reno, who said his company is about to add another

work shift and many manufacturers see this as a time for

optimism.

Ray Bacon of the Nevada Manufacturers, the NBC

breakfast panel moderator, chimed in on the China-in-the-cross-hairs theme, yet

he also warned of problems that could still trip Nevada industry up over

time.

“We can do on-shoring,” Bacon said. “We can be

competitive.” He said China’s wages go up 15 percent annually, and the Asia

giant’s industrial operations aren’t efficient.

But he criticized a proposed Nevada margins tax

on business and any altering of the state’s regulatory environment in ways that

would hamper Silver State firms, whether current companies or those

transplanting to Nevada as the economy keeps recovering.

Bacon cheered the business breakfast audience

by saying the state margins tax plan can be turned away when its fate is decided

in November. He said signs indicate labor organizations with workers in the

private economy won’t or may not support the tax.

“This thing can be defeated at the ballot box,”

he said.

John Barrette

jbarrette@nevadaappeal.com

January 22, 2014

John Barrette / jbarrette@nevadaappeal.com | Nevada Appeal

Founder/CEO Gerd Poppinga left & GM Sven Klatt at Vineburg Machining earlier this week.

Vineburg Machining Inc. recently moved to new and larger digs, has purchased top-flight equipment and projects that 20 percent output gains are in the offing.

The closely held corporation, which has a Carson City address at 26 Stokes Drive in a Mound House industrial park, moved into a plant of nearly 19,000 square feet there, leaving behind a 12,500-square-foot facility a couple of blocks away on Brown Drive. The firm, founded by President and CEO Gerd Poppinga, has 32 employees along with the expensive milling equipment.

“The people who work here have an opportunity to learn state-of-the-art machining,” said the founder. The comment came during an interview with him; Sven Klatt, Vineburg’s general manager; and Poppinga’s son, also named Gerd, Vineburg’s vice president. The elder Poppinga and Klatt said it is difficult to predict gains, but Klatt ventured the 20 percent projection.

“We’re going to grow,” the founder agreed, “by output.”

The trio recounted the firm’s history, saying it reached nearly 100 workers in 1999 while still in California. But then it fell on tough times, dropping to 40 workers in 2003. The decision to move to Nevada was made late that year, and 17 made the trek to join in the permanent relocation to the Carson City area.

The firm immediately hired five, but the economy tightened and Vineburg’s crew dropped to a dozen in about 2005-06.

Now back to more than 30 employees, the company makes an array of parts and products using the new machinery.

“It enhances quality drastically,” said Klatt, who joined the firm when he moved to the United States from Germany in 1998. He said that when he arrived, he didn’t speak English.

He made a connection then with the Vineburg founder through a mutual acquaintance in part because Poppinga, who previously emigrated from Germany, had gone to the same machining apprenticeship school in Oldenburg 30 years earlier than Klatt. Oldenburg is in northern Germany.

The firm’s vice president, meanwhile, said Vineburg made it through difficult times that preceded recent gains by doing machining for medical needs and commercial locks. He and his father particularly focused on the commercial lock market as a savior during the downturn years.

“The worldwide scope of it has helped,” said the younger Poppinga.

Klatt said perhaps $2 million worth of the best machining equipment purchased the past three years.

In addition to putting in many hours at the plant, Klatt teaches at Western Nevada College, a role that in part stems from one of the industry’s dicey problems. Vineburg’s founder chimed in, saying the lack of a trained work force for machining and manufacturing can be a problem nationwide.

WNC News & Notes: Students get skill boost, a shot at employment

Manufacturers join forces, create ‘virtual assembly line’

The Western Nevada College Manufacturing Lab received $1 million in new machinery.

Expand Photo Courtesy | Nevada Appeal

July 27, 2013

Austin Lambert's "The Archer" has found a permanent home outside the WNC Andy Buttie Welding Technology Center.

Machine

tool technology students at Western Nevada College will benefit twofold

from new machinery provided by Gosiger Inc. and a grant that will

upgrade the hands-on technology center.

Not

only will WNC students learn to use some of the latest computer

numerical control machines, they will be under consideration for

employment by local manufacturers that visit the campus to see

demonstrations of the machines.

“It’s

a win-win for us,” said machine tool technology Professor Paul

Eastwood. “They lend us the machines for instructional purposes, and

they come in to demonstrate them to local manufacturers.

“It’s a good idea because when we invite the local manufacturers to our facility, they often ask us about potential employees.”

The

Okuma Turning Center and Harding Milling Center are CNC machines from

Gosiger’s Fullerton, Calif., plant. By moving them to the Woody Wurster

Machine Tool Technology Center at WNC, students can learn the specific

skills that manufacturers are using.

Each

of the CNC machines will use Mastercam software, giving students

another skill that should benefit them as they seek employment.

“It’s

one that quite a few local manufacturers use, so the students are more

appealing,” Eastwood said. “With the machines and software coming in, we

are upgraded with the newest equipment on the market.”

Sven

Klatt, who began teaching CNC programming at WNC last year, helped

broker the deal for the new machinery after being approached by Gosiger

representatives.

“They

had done cooperative programs with schools throughout the United

States. I put the right people at the college in contact with Gosiger,”

Klatt said.

In

addition, a separate grant has allowed WNC to purchase a Haas CNC

Turning Center machine, which has just arrived at the college.

“There’s

$1 million of new technology at the machine shop,” said Klatt, general

manager of Vineburg Machining Inc. of Mound House. “I don’t know of any

other college adding that much new machining technology. It’s a huge

improvement, something that the private sector and the college worked

hand in hand to get off the ground. It’s going to be a win for all of

us.”

Eastwood said the machines have been installed and will be operational in time for fall classes.

Student turns schoolwork into art

Western

Nevada College student Austin Lambert has combined his welding skills

with his artistic talents to create an award-winning sculpture. Now, his

work has found a permanent home outside the WNC Andy Butti Welding

Technology Center.

“The

Archer,” a life-size sculpture of a man pulling back a bow, took first

place in the ceramics and sculpture category during the college’s 2013

student art show in Carson City.

Lambert

originally welded a smaller version of the sculpture while attending

Douglas High School in Minden, then created the life-size tin version in

his welding class during the spring semester. Lambert said he was

inspired to create a larger rendition to display outside the Welding

Technology Center, offering it a signature piece of art.

“I like the way it turned out,” Lambert said. “I take to the rustic side of art — sword fighting. I like the medieval (period).”

Manufacturers join forces, create ‘virtual assembly line’

Northern Nevada manufacturers are banding together to build a virtual one-stop shop for customers.

The idea is to link local manufacturers with varying skills and expertise in a dispersed assembly line that can quickly respond to orders. The goal is to attract more work and in turn create more jobs and turn the area into a haven for contract manufacturing.

“Manufacturing used to be all in one building, but in today’s world there is customization,” says Susan Clark, founder and president of Reno’s Nevada Venture Accelerator 250 known as NVA250, which is spearheading the effort. “People want (products with) mass-produced price points but customized for them. Think of it as a virtual manufacturing hub.”

The backbone of the project is a supplier database built and hosted by NVA250. That database was funded in part by the Governor’s Office of Economic Development, which has identified manufacturing as a key industry in the state’s economic future.

The database contains detailed information on 200 manufacturers that can be searched using precise criteria such as materials, machine types and part size. The group is continuing to develop it and plans to add more features, including an interface to computer-aided design programs which would assemble a Nevada-based supply chain for a product as it’s being designed.

But NVA250 is working with a smaller group of manufacturers — about 15 right now, says Clark — to coordinate their work on some initial forays into producing products using the team approach.

One of the first projects the group has worked on is parts for a motorcycle engine being built by a California racing outfit. (Customer names aren’t revealed because manufacturers’ work is done under nondisclosure agreements.)

“One of the success stories of these manufacturing clusters is the UK-based motorsport market,” says John Kucjaz, a manufacturer who moved here from Michigan and is developing component technology to improve the performance of hybrid vehicles. “There is this amazing cluster in southwestern England that caters to that industry.”

The California customer hopes to duplicate that environment here, says Kucjaz, who says he moved to northern Nevada largely because of the manufacturing know-how.

Several manufacturers are working on the project, passing off parts to one another as the pieces move back and forth down the virtual assembly line. Advanced Materials and Manufacturing Technology, for example, is developing material for a piston and needed a 3D scan of the part. So Tripp Enterprises Inc. in Sparks scanned the piston for AM2T.

“We gave them a piston and they did the 3D scan and produced data files for a CNC (computer numerical control) program which we in turn gave to a manufacturer in Carson City and said here’s the files, here’s the materials, now fabricate the pistons,” says AM2T owner Henry Meeks.

The machine shop in the production chain was Vineburg Machining Inc.

Meeks estimates having access to Tripp’s 3D scanner cut production time in half.

Meanwhile, Betra Manufacturing is working on incorporating in the engine the lightweight aluminum it is beginning to work with.

“There’s a lot of demand for the material, anywhere where weight saving is important,” says Larry Kondik, owner of the Carson City foundry. “I’m making cases for the outside the engine.”

So far, all the manufacturers are pleased with the results.

“It’s really a way for manufacturers in this area to come together and understand each other’s capabilities and strengths, and then organize to create an offering that’s compelling to potential customers,” says Frank Terrasas Jr., marketing and business development at Tripp. “Rather than doing it individually, what NVA250 is saying, and I think it’s brilliant, is this is what we can do as a region.”

By: Anne Knowles, NNBW

May 13, 2013

In his own words: Gerd G. Poppinga of Vineburg Machining

By: NNBW staff, 7/5/2010

Northern Nevada Business Weekly: Tell us about your company— its specialties, its history, the size of its staff:

Gerd G. Poppinga: Vineburg Machining, Inc. is a 33-year-old, family-owned and certified full-service machining job shop. We serve multi-industry original equipment manufacturers and manufacturers throughout the U.S. We currently machine 7 to 10 million custom parts a year from all types of metals, for companies like Schlage-Lock (Ingersoll-Rand). We moved to Mound House from Sonoma, Calif., in 2003, with a staff of 18, plus their families.

NNBW: What role do you play in the company? Poppinga: My responsibilities specifically include ownership concerns, project estimator, oversee sales and marketing, and technical and engineering; support of staff and customer service.

NNBW: How did you get into this profession? Poppinga: Through a trade school and apprenticeship in Germany.

NNBW: What is something no one knows about your job? Poppinga: The amount of knowledge needed to perform all aspects of running a machining business from technical, to accounting, to sales and marketing. Even more so, the smarts to survive the ups and downs of business cycles and challenges like offshore outsourcing, 9/11, and the most recent recession.

NNBW: If you could have had any other profession what would it have been? Why wasnt it your first choice? Poppinga: After my apprenticeship in machining, I wanted to become an engineer. Instead I first came to the U.S. to learn English, and stayed after two years in the military. I continued on in machining, started a family and eventually started my own business. At one time I wanted to be a forest ranger because I love the outdoors, then a cook because of my love of different foods. The only solid opportunity at the time though was to continue in machining.

NNBW: What do you like to do when youre not working? Poppinga: Motorcycling, hiking and golf.

NNBW: Have any advice for someone who wants to enter your profession? Poppinga: Its a tough choice but rewarding if youre good with your hands and love to create something people will use.

NNBW: If you could have one superpower, what would it be and why would you want it?

Poppinga: I would just love to have the power to improve the human condition.

NNBW: What person, living or dead, would you most like to have dinner with, and why?

Poppinga: Multiple people actually; mainly those who wrote the U.S. Constitution because they changed my thinking about what freedom and opportunity mean.

NNBW: Whats the best advice anyone ever gave you?

Poppinga: Do unto others as you would have them do unto you.

NNBW: What do you like most about your job? What do you like least?

Poppinga: I enjoy technical challenges, and dislike repetitive aspects of the job.

The basics:

Name: Gerd G. Poppinga, president, Vineburg Machining Inc.

How long have you been in this job? Since 1977 (33 years)

How long in the profession? Since 1961 Education: Trade school in Germany, then college in the U.S.

Best book youve read? “Birdman”

Whats on your iPod? Diverse selectionoldies, rock, country western, classical, and opera.

The best movie ever? “Airplane”

Spouse, kids or pets? Ismenia, wife of 42 years and two kids. No pets.

Machine shop bores into specialty manufacturing niche

Pat Patera, 9/15/2008

Vineburg Machining Inc. has fingers in a lot of products. The Mound House shop turns out parts for everything from race cars, surgical units, military medical units, locks and pet products to Humvee repair kit parts.“We go through a million pounds of metal a year,” says company owner Gerd G. Poppinga. His son, Gerd E. Poppinga, director of operations, tells how the company needed 12 flatbed trailers to move Vineburgs massive milling machines from Sonoma five years back.For decades, the company turned out parts with those 15 Acme multi-spindle machines that dated from the World War II era.

And while those workhorses still pull their weight, since moving to Mound House the shop floor has seen dramatic change with the addition of eight CNC — Computerized Numeric Control — machines, costing about $250,000 each.For Vineburg, the Sept. 11 attacks in 2001 provided the impetus for change. The resulting economic seizure combined with the trend toward outsourcing work to China to deliver a devastating double punch.

“With the general economy not going so well, we needed to cut costs and look at a different business model,” says the elder Poppinga. “I looked at where manufacturing would be in five to 10 years. We thought of specialty markets within the greater machine industry.”He was proved right. However, the move from mass milling to specialty provider meant shrinking the company, which employed 100 at its peak, to just 25.

The move to Mound House was a further cost-cutting move. But it delivered a pleasant plus in the form of a reliable power grid, says the younger Poppinga.“In California,” he says, “we were constantly suffering brownouts.” Before the move, the Poppinga family already knew the Reno-Tahoe area as tourists. And, having bought a house at Dayton Valley Golf Course as an investment property, the elder Poppinga knew of the industrial park at Mound House.

He worked with Kris Holt, then leasing agent at Grubb & Ellis commercial property, to lease a 13,000-square-foot building at Mound House.

Of Vineburgs 25 employees in Sonoma, 18 chose to move their families to Nevada. “I never readjusted their pay,” says Poppinga, which sweetened the deal. But those longtime machinists were familiar with the manual Acme machines used for high-volume runs. The companys move to the more precise runs required for specialty medical and automotive parts required more workers on the computerized machines.

For the most part, the younger Poppinga, who has a degree in strategic business management, helped train employees with the new technology. Training remains an ongoing issue, as each new job comes into the shop.

The best way to confront the shortage of skilled workers in northern Nevada, says the companys founder, is to keep existing employees on board.“Treat them like a family member,” he says. “We provide everything: above-average income and training and pension. We pay bonuses when were doing well. And we hold company lunches, picnics and outings.” Finally, he adds, “I trust them, I dont look over their shoulders.”The old guard machinists, those able to set up a job by hand, are retiring — and the dearth of young people entering the trades has left a void. But new grads holding computer degrees also need mechanical aptitude, says the younger Poppinga, as well as the ability to visualize in three dimensions.

Competition from China remains tough, but the Mound House company contends that turnaround time for a job at Vineburg is four weeks compared to six months for work sent overseas.An overseas order must be big enough to fill a shipping container, and an independent inspector often is needed on-site to oversee offshore manufacturing. However, the elder Poppinga points to a neighboring company that had to junk 60 percent of an order, incorrectly made. “Yet its still cheaper for them to outsource to China,” he says.

While the company has kept some former customers whose jobs run on the old Acme machines, it still needs to find new customers. The companys owner makes cold calls from manufacturing guides. Of his firms success, the founder, who as a young man immigrated from Germany, says, “Only in America.”

Workforce Training

Employment Training Panel (ETP) Funds CASE STUDY 3

Company Profile-

Vineburg Machining, Inc. (VMI) is a Sonoma-based company that creates machined parts for construction tools, medical implements and automotive parts. Their client base is local, nation-wide and international.

Challenge-

VMI's president, Gerd Poppinga was interested in a variety of company-wide training. The VMI management team, composed of managers, supervisors and team leaders, had just been formed and needed management training. Increasing customer demands with more complex specifications and a general upgrading of processes was pushing the need for training on the line. Poppinga also wanted training in ISO 9000 compliance, statistical training and machine shop blueprint reading.

The company was concerned with maintaining production rates while employees were off line in training. Although, training was

a priority for this manufacturing company, they were also

concerned about the cost.

Solution-

One of VMI's managers learned about Employment Training Panel (ETP) grants from a consultant whose services were too expensive for the company. When they discovered SRJC's

Workforce Training Department could provide the training and access to ETP funds, which would cover most of the training costs, they signed up.

The training plan for the forty production employees included Problem-solving and Statistical Process Control. Blueprint Reading was added for the machine shop, and managers took an additional 24 hours of Quality Management training. To launch the program SRJC's Workforce Training Coordinator, working with Poppinga and his Technical Support Manager, Bill Poleshuk planned three all-day Saturday sessions to introduce ISO to all of VMI employees.

Impact-

Poleshuk says that many in VMI's blue-collar work force did not initially see the value of leaving the production line for training. One of the outcomes of the training was that employees became more proactive and questioning in their jobs. “Now our employees are confident asking for help because they see it as a part of their job. The company operates more like an inverted pyramid. Rather than waiting to be told what to do and when, employees do the work and tell management what they need,” commented Poleshuk.

Besides upgrading the standards and practices at VMI, Poleshuk reported a result that surprised the entire management team. When they reviewed financial records for the training period, production was not adversely affected as had been anticipated. “We expected a negative financial impact, and were very pleased that we could provide training and stay profitable during the same period,” Poleshuk added.

Mound House Machine Shop builds bonds in N. Nevada

Becky Bosshart

Appeal Staff Writer, bbosshart@nevadaappeal.com

May 30, 2005

MOUND HOUSE - Gerd Poppinga had to make the hardest decision to ever confront a business owner.

Poppinga, 59, started his business in 1977 in Sonoma, Calif., but moved it to Mound House recently for economic reasons. About half of his 35 employees decided to also make the move. So in November 2003, the multimillion-dollar equipment essential to Vineburg Machining Inc.'s business was transported on 14 semi-trucks to Northern Nevada.

Poppinga was born in Germany, but arrived in California just in time to be drafted into the Vietnam War, where he served from 1966 to 1968. Soon after returning, he married a Panamanian woman named Ismenia, and they have two children. His son, Gerd Jr./COO, also works at Vineburg Machining.

"We used to have 90 employees in 2000, but due to the recession, our business was slowly going down in the number of employees," he said. "We dropped to 35 employees at the end of 2002-2003."

Poppinga said the semi-conductor industry was in decline so he decided to downsize. His biggest customer was going into a redesign; other customers were going overseas. Poppinga already owned a house in Dayton, so this area became his first choice.

"When I had to make the decision, I looked at the business climate in Nevada and its infrastructure. Our type of business relies on raw materials from the Bay area and Southern California. I found that Mound House had a good support line."

His 13,000-square-foot shop is broken into two parts, but it all sounds the same: the grinding cacophony of industry. One half contains about $1.1 million in computer-operated machines. These digital machines are for the precise pieces, but they have a short lifetime and need diligent maintenance.

The other half of the shop is dominated by 13 mass-producing machines, each worth from $50,000 to $150,000. These machines are for producing high volumes. Poppinga said they're all American-made and will last for decades.

Although he isn't employing the same number of people that he had before the recession, 25 machinists work in the machine shop, Poppinga said he is establishing bonds with other industry in Carson City. Vineburg is a contract shop that doesn't make any of its own products. It has contracts to make such things as door locks, parts for fire pokers, orthopedic devices, animal feeders and racing cars. The products are shipped to Mexico, Colorado, California and Nevada. "I like to work with the engineers from various companies that we do work for. They come to us with a specialized process. They want to take a new design to market, and they come to us to make it as low-cost as possible."

|