About Us

Vineburg Machining, Inc.

Established in Sonoma, CA, in 1977, Vineburg Machining, Inc. (VMI) has evolved into a premier precision machining company. With a state-of-the-art production facility in Carson City, NV, we’ve expanded to better serve our clients while upholding the commitment to excellence that has defined us for nearly five decades.

What Sets VMI Apart?

We leverage cutting-edge technology, operating ten 5-axis CNC milling machines alongside advanced robotics to maximize efficiency and precision in our machining processes.

What are 5 Axis machines?

A 5-axis CNC can move the cutting tool and the part at the same time, letting it machine complex geometries in one setup instead of many.

That means:

tighter tolerance tighter tolerance

smoother surface finishes smoother surface finishes

fewer tool changes fewer tool changes

much faster production much faster production

Additionally, we’ve implemented three 40-pallet systems integrated with our 5-axis CNC mills for fully automated, 24/7 unmanned operation. To ensure top-tier quality, we’ve equipped these systems with a Coordinate Measuring Machine (CMM) for 100% inspection of all pertinent measurements. Each part can be serialized and documented, providing complete traceability and assurance of quality.

This advanced automation enables VMI to lower costs for our customers, improve “Just-In-Time” delivery, and reduce their inventory costs.

Vineburg Machining is doing their part to help revitalize and advance American Manufacturing. We provide solutions to critical challenges including attracting a skilled workforce, strengthening supply chains, and supporting technology and innovation.

Innovative and Reliable Solutions

At VMI, our expertise spans multiple industries, utilizing systems like Kanban, Consignment, Just-In-Time (JIT), and Supplier-Owned Managed Inventory (SOMI). Our sophisticated software ensures seamless scheduling, in-house operations, and real-time tracking, allowing us to provide updates to our clients at a moment’s notice. To meet production demands, we operate three shifts and extend hours on weekends when needed.

Commitment to Quality

As an AS9100 certified company, VMI is dedicated to the highest quality standards. From material sourcing to comprehensive project documentation, we deliver reliability, performance, and excellence throughout the entire fabrication process.

Why Choose VMI?

-

Proven expertise in delivering high-tolerance machined components since 1977.

-

Serving the most demanding industries with precision and innovation.

-

Advanced automation and inspection systems for cost efficiency and quality assurance.

-

Tailored manufacturing solutions to eliminate bottlenecks and meet unique challenges.

Experience Matters

Turn your concept into reality with VMI. Contact us today to discover how we can exceed your machining expectations.

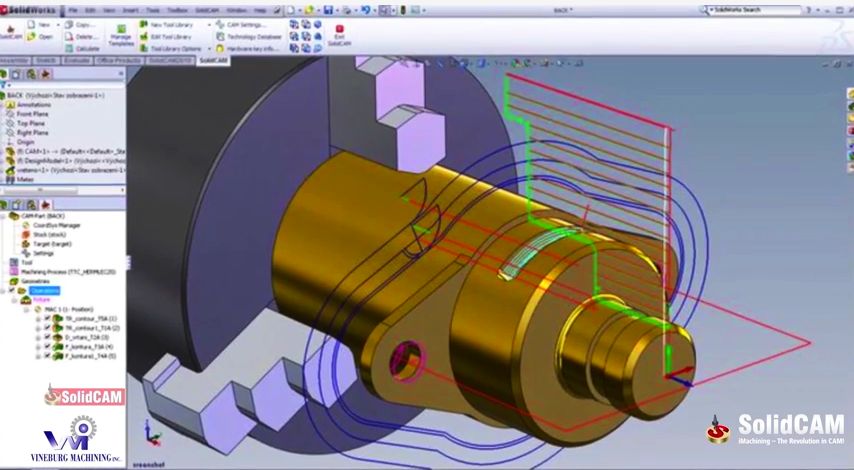

VMI utilizes up-to-date CAD/CAM programs that support a variety

of file formats making it easy for customers and our staff to

communicate during the design phase.

Our system at VMI accepts all versions of electronic drawings, prints and designs such as:

Mastercam Mastercam

AutoCAD AutoCAD

SolidWorks SolidWorks

SolidCam SolidCam

PDF PDF

Raster/Vector Raster/Vector

3-D Modeling Services Available! Industries Served:

Contact us for more information on how we can help with modeling your upcoming projects or for helping engineer a new product line for machining.

Industries Served:

Medical, Military, Automotive, Commercial, OEM's, Architectural Hardware and Aerospace Components to name a few.

Machining Specialty:

VMI has gained experience in the manufacturing of gun components as well as machining castings.

Prototype to Production Machining:

Planning to develop a new product or idea begins with a proverbial light-bulb moment; that “a-ha!” sensation when inspiration hits, and something either entirely unique or an innovative twist on an existing idea materializes. But unless you have your own job shop at your disposal, chances are you’ll need to partner up with a manufacturer to turn your product idea into a reality. That's where we come in. Contact us today and find out how to get started!

Supplier Data Protection & Cybersecurity

As a CMMC Level 2/NIST 800-171 compliant company we take security very seriously. Together we deliver advanced products & services that solve some of the worlds most difficult challenges. This makes Vineburg Machining Inc, its suppliers and its customers potential targets for cyber attacks. It's ever important that we understand these threats and the joint responsibility necessary to secure our supply chain.

The DOD published DFARS 252.204-7012, Safeguarding Covered Defense Information and Cyber Reporting in an effort to prevent improper access of important unclassified information in the supply base. The DFARS 252.204-7012 clause includes the following key requirements:

Adequate Security

Contractors must provide adequate security on all covered contractor information systems. A “Covered contractor information system” is defined as an unclassified information system that is owned, or operated by or for, a contractor and that processes, stores, or transmits covered defense information.

Cyber Incident Reporting

When a cyber incident is discovered, contractors must conduct a review for evidence of compromise of covered defense information and report this to the DoD at http://dibnet.dod.mil and VMI within 72 hours. A “Cyber incident” is defined as actions taken through the use of computer networks that result in a compromise or an actual or potentially adverse effect on an information system and/or the information residing therein.

Supplier Flow Down

When engaging with other suppliers that require access to covered defense information in performance of a contract, include the DFARS 252.204-7012 clause in any subcontracts, or similar contractual instruments with those suppliers.

|